It is used for the safety information traceability management of gas cylinders, and the NFC application example of the device is quickly located

NFC for Gas Tank Application

Gas tank industry

What does NFC technology bring to the innovative gas tank industry?

NFC tags, as a real-time and readable small storage chip, can help manufacturers optimize inspection processes, easily track and manage, bid farewell to manual logs, embrace digital convenience, and reduce security risks caused by inadequate inspections. Install a card reader at the warehouse entrance to seamlessly track and manage gas cylinders. The embedded information can be updated in real-time to achieve accurate and up-to-date records. This not only simplifies inventory management, but also greatly reduces the risk of errors and enables traceability of product entry and exit data. Installing labels on gas cylinders allows for monitoring of their service life at any time, timely refurbishment and maintenance, improving usage safety, and screening to automate the gas cylinder filling process.

Application

NFC label solution in the field of gas tanks

Example of NFC application for controllability in gas cylinder filling process

Case

Case Studies of NFC Applications in Gas Tanks

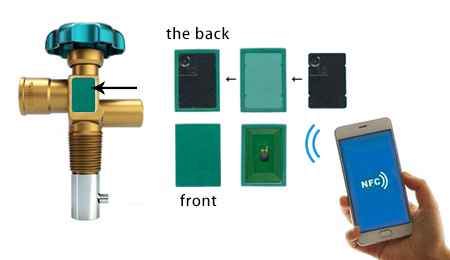

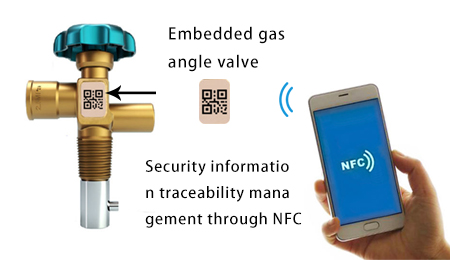

NFC labels help you with safety information traceability management of gas cylinders and quickly locate devices

The NFC label is embedded on the side of the gas corner valve of each gas cylinder, which is convenient for manufacturers to inspect, locate and track, track and manage the situation of each gas cylinder in real time, and reduce safety risks.

Basic Parameters

| Installation area | Embedded gas angle valve |

| size | 20*16mm |

| Material | ABS |

| Read Range | 10-25mm (related to card reader equipment) |

| Operating temperature | -20 to 85 ℃ |

Electric Parameters

| Chip Type | MIFARE Classic EV1 /S50 |

| Frequency | 13.56Mhz |

| agreement | 14443a |

| Erasure lifespan | 100000 times |

| thickness | 4.5mm |

The advantages customers can get

- Security Informatization Traceability Management

- Quick positioning device

- Reduce safety hazards

- Say goodbye to manual logging and embrace digital convenience

NFC labels help you control the filling process

Attach NFC labels to gas cylinders, monitor their service life at any time, read relevant information, and filter them to the filling production line to achieve limited filling of dedicated cylinders and avoid refilling of scrapped cylinders, achieving safety and controllability.

Basic Parameters

| Installation area | Embedded gas angle valve |

| Dimensions | 22*16mm |

| size | ABS |

| Read Range | 10-25mm (related to card reader equipment) |

| Operating temperature | -20 to 85 ℃ |

Basic Parameters

| Chip Type | 213 |

| Frequency | 13.56Mhz |

| agreement | ISO 14443-a |

| Erasure lifespan | 100000 times |

| thickness | 3.5mm |

The advantages customers can get

- Monitor the service life at any time

- Automated filling of gas cylinders

- Safe and controllable

NFC Chips

Common NFC Chips for Gas Cylinders

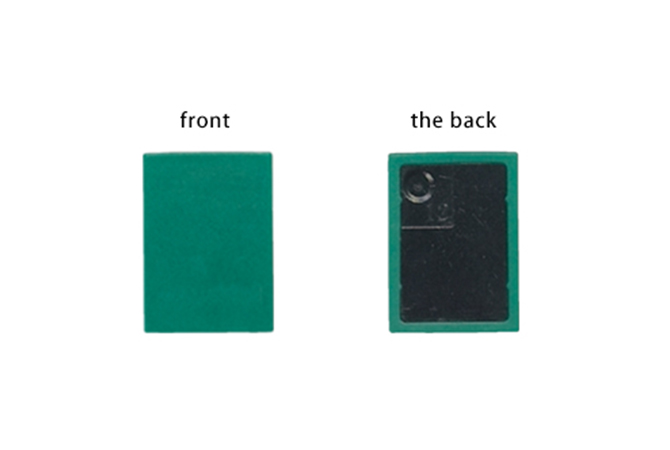

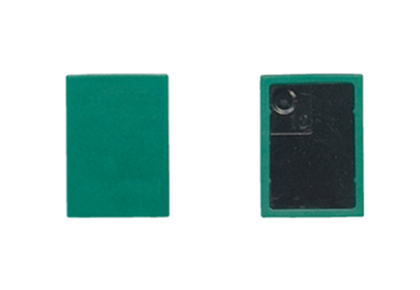

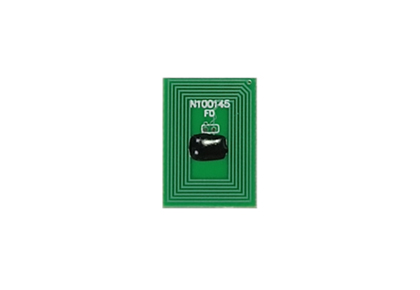

The 20*16mm high frequency and high temperature resistant gas Angle valve is applied with MIFARE Classic EV1 /S50 chip

High frequency and high temperature resistance 213 chip automatic filling gas cylinder with NFC electronic label 22*16mm

RFID high temperature resistant PCB waterproof Electronic label Asset Management NFC label 10 * 14.5mm

Contact DCNFC to Start Your NEC Tag

- Quick Quotation

- Name

- Tel

Sign Up Out Newletter

- Name

- Tel

- *Title

- *Content